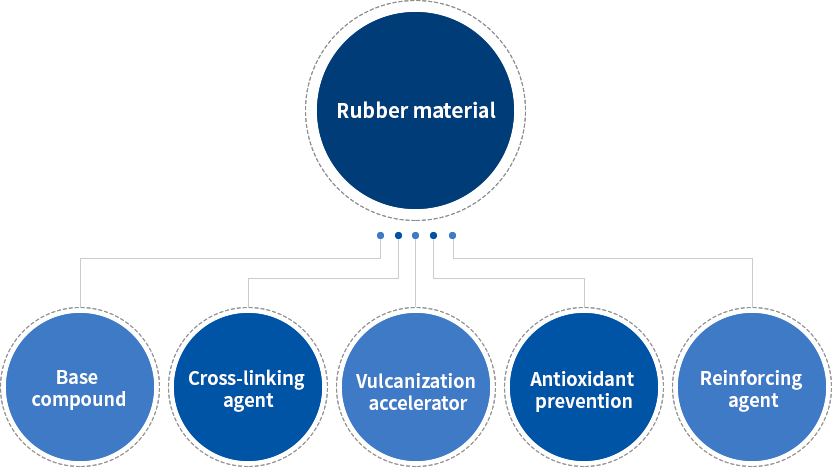

Material technology

Material development in line with the environment where the products are mounted

Products produced by selecting and applying materials optimized for the differences in the usage environment of each customer’s products.

- Identification of the physical and chemical properties of each material

- Analysis and development of physical and chemical mechanisms that occur in mixing

Derivation of optimal mixing conditions

Development examples

-

NEP acquisition for nuclear power development materials -

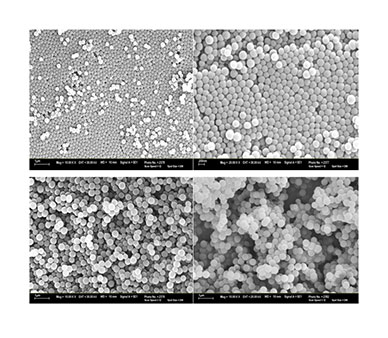

Composite material

(nanoparticle) -

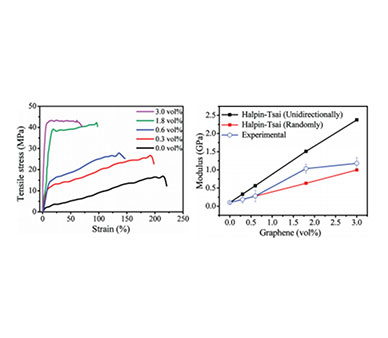

Composite material

(graphene)

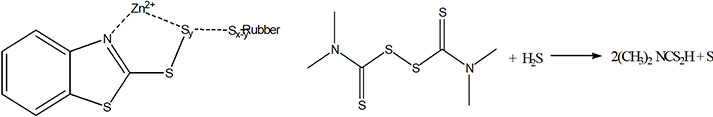

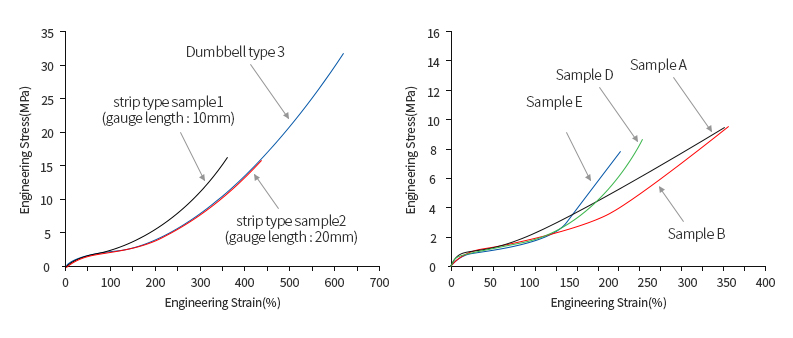

Verification and analysis of rubber materials in development

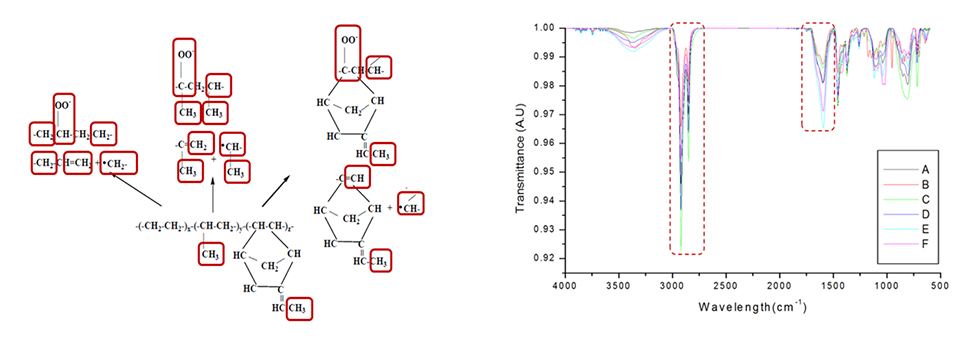

- Verification of mixing mechanisms by analyzing the properties of each material

- Acquisition of the property controlling technologies for rubber materials by controlling mixing ratio

- Verification of the integrity and mechanical properties of rubber materials through analysis equipment

- Deduction of the optimal conditions and environment by comparing physical properties according to linking conditions

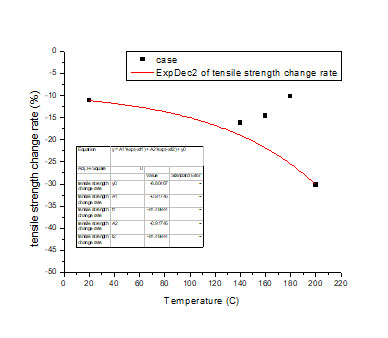

- Verification of the durability by testing the usage environment for each product

-

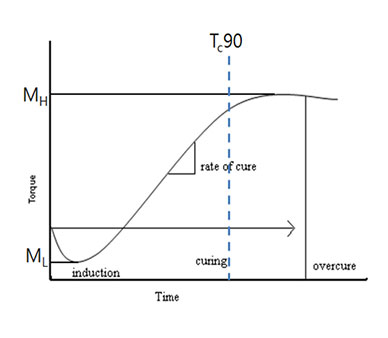

Analysis of the material properties (rheometer) -

Measurement and analysis of mechanical properties

-

Evaluation of the effects of irradiation -

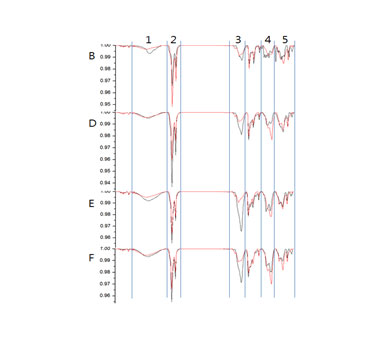

Photodegradation evaluation (FT-IR) -

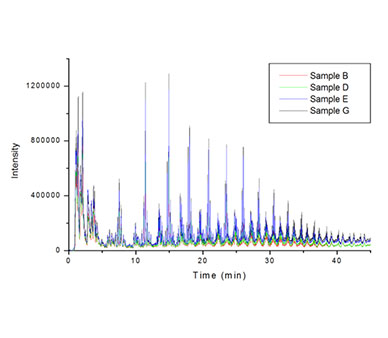

Monomer analysis and evaluation (reproducibility)

-

EPDM decomposition mechanism (FT-IR)